Health, Wellness and Safety

We believe that the health of our business depends on the health and safety of our people. From giving our employees and their families the means to manage their health to making workplaces and commutes safer, we continue to make measurable changes in the lives of our people worldwide.

Healthcare

Our healthcare philosophy — Healthy Together — focuses on helping employees and family members to make informed healthcare decisions and gives them the tools to manage their health and well-being. Employees can also access various health and wellness programs through the healthcare carriers they select. As part of the Healthy Together program, the company provides free, confidential wellness screenings on an annual basis so employees can identify key health risks and work with their primary care physician. Xerox also contracted with various wellness vendors to assist employees in developing action plans to address these risks. We provide easy access to meaningful, timely and relevant information through a single portal, simplifying the experience of choosing and using benefits. Currently, this program is available to employees in the United States.

Employee Safety

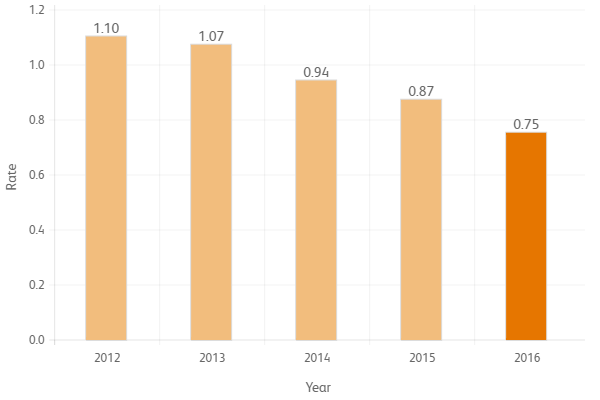

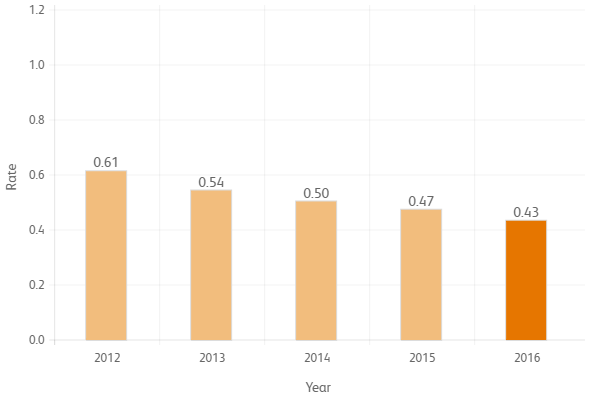

Xerox is committed to maintaining a safe work environment for our people. We strive toward a goal of zero workplace injuries, continually decreasing the frequency and severity of injuries every year. In 2016, within our global Technology operations the total recordable injury (TRI) rate decreased by 13% and day away from work case (DAFW) rate decreased by 9% from 2015 levels. In addition, across all of our U.S. operations, the DAFW frequency rate decreased by 6%, which is reflective of success in preventing the more serious injuries. Overall, these improvements have continued since 2012 and are a result of the increased safety awareness and communications to our employees and focused safety management processes within our management teams.

Total Recordable Incident (TRI) Rate

Day Away from Work (DAFW) Rate

1Data in this section includes Xerox Technology Operations but excludes Global Imaging Services operations.

We have in place a robust, worldwide incident reporting process. This, in combination with workplace safety inspections and hazard analysis, focusses our safety improvement efforts where we can make the most impact on preventing incidents and where populations are most at risk. Employee safety communications take a variety of forms, given the great diversity in our operations and workplaces. A number of methods are used to keep employee safety awareness high, including site specific hazard management, off the job safety information and unique safety concerns that may be endemic to the geography.

Safe Facilities

In order to ensure that all Xerox owned and leased facilities meet our stringent fire and life safety requirements, all real estate transactions are reviewed by the Environment, Health, Safety and Sustainability (EHS&S) organization prior to occupying. Xerox fire safety and life safety requirements have been established and are implemented worldwide, regardless of location, size of the facility or occupancy classification. The focus of the safety review is Life Safety requirements, including safe egress in an emergency, fire and incident prevention, early detection, suppression, occupant notification and prompt emergency response. These reviews also ensure that building specific emergency plans are implemented and updated, and that emergency drills are completed at least on an annual basis.

Audit Program

A well-established internal audit program measures our success in implementing corporate standards, allows us to share best practices and helps us validate regulatory compliance. Audits at major operations are conducted once every three to five years (or sooner, based on performance). The frequency and the focus of the audits are based on the type of operations and the inherent risks associated with the operations.

Xerox audit teams evaluate operations against our internal standards, external regulations and industry guidelines. The teams also evaluate management system performance. With the assistance of the local managers and support staff, action plans are developed and deficiencies corrected. Senior management pays particular attention to situations with the potential to pose a significant risk of environmental damage, serious injury to employees or regulatory non-compliance. Xerox’s audit program is an important mechanism for identifying and correcting performance gaps.

Emergency Preparedness

Because emergencies and disasters often strike without warning, Xerox has implemented an emergency preparedness and response program to help protect the safety of our employees, the surrounding communities and the environment.

To prepare for emergencies, Xerox facilities worldwide have implemented site-specific Emergency Preparedness Plans to assist with the development and execution of appropriate actions in response to local emergencies. Our plans account for common emergencies, such as responding to fires, for weather-related emergencies such as tornadoes and hurricanes, and for more location-specific emergencies, such as responding to earthquakes and radiological emergencies. We also include resources and procedures for first aid medical response in the event of an injury or illness to an employee in our facilities. In our more complex and higher hazard operations, we have Medical Emergency Response Teams (MERTs). These MERT employees are provided with the training and equipment necessary to render quick response to stabilize the medical emergency until more advanced medical support arrives.

Shelter-in-Place procedures have also been implemented to protect our employees from emergency situations that occur outside of our facilities.

In addition to emergency action plans that are established at the local operation level, there are preparedness plans at the corporate level including major incident response, crisis management and pandemic preparedness. These plans have been designed with a central corporate strategy that utilizes an incident command structure. Incident Response Managers are responsible for local/regional tactical and emergency response, coordinating efforts at their respective locations with the Corporate Crisis Management Team and addressing local business operations issues. Response coordination and integration are part of the planning process.

All preparedness plans are regularly tested for effectiveness through management reviews, corporate audits and annual drills. Any discrepancies are noted and corrective actions are implemented. Following an emergency, Business Resumption Plans are put into action to ensure the business operations are quickly restored after the incident.

Motor Vehicle Safety

Motor vehicle safety is a key component of our safety initiatives. We have a company car program that specifies motor vehicle safety requirements for our drivers and accident prevention and reporting processes. Employee driving records are reviewed on a regular basis, and we provide remedial motor vehicle safety training to improve awareness and competency. Motor vehicle accidents are tracked by frequency and type and are reported to the management team.

We also participate on fleet safety benchmark forums to keep up to date on the latest motor vehicle safety practices and technologies and to share Xerox’s best practices with our peers.

The use of cell phones in any company vehicle is restricted. Texting is forbidden while the vehicle is moving. Employees who need to use their phones in the car are instructed to find a safe place to stop.

A comprehensive safety review is conducted on any vehicle model prior to it being accepted as part of the Xerox fleet. We review the safety ratings and crash test results of candidate vehicles and require safety features such as daytime running lights and safety barriers between the driver’s seat and storage areas.

Ergonomics

Because musculoskeletal disorders represent a significant portion of our work-related injuries, we work to minimize the risk factors as a job is designed. We study exposure to ergonomic hazards and raise awareness with employees so they can make improvements to their workstations.

Learn more about what we’re doing to prevent workplace injuries. +

From manufacturing operations to office work, we continue to study the causes and potential remedies for workplace injuries. The following provides some brief highlights

- Manufacturing Operations: Workstation evaluations are conducted in Xerox facilities worldwide for ergonomic hazards based upon risk profile and injury experience. Ergonomic enhancements such as tilt tables, lifts and hoists make it easier for employees to maneuver parts and equipment during assembly.

- Machine Service: Xerox Customer Service Engineers’ (CSEs) exposure to ergonomic hazards has been studied. The findings have helped us select tools and develop procedures to mitigate risk of musculoskeletal disorders. Throughout the equipment design process, evaluations are done to assess risks for our CSEs. The best time to make a modification is when a product is still in the design or early test phases.

- Office Ergonomics: Our largest employee population is office-based. Raising awareness and helping employees make effective workstation changes is critical to minimizing risk for this population. We created computer-based training on ergonomics principles and practices. This method of delivery enables employees to go through needed training programs at a time that minimizes business interruptions.

Asset Protection and Fire Safety

The Xerox Asset Protection and Fire Safety Program provides fire-safe workplaces and limits the potential for losses to Xerox equipment and property from fire, explosion and natural hazards, such as windstorms, snow-loading collapse and floods. The program includes periodic inspections, management reviews of findings, and mitigation planning. Our philosophy is to maintain our higher-valued locations to a “Highly Protected Risk” standard. In addition, locations are reviewed for conformance to Xerox standards and recognized fire, property and life safety standards. We continue to demonstrate excellent loss control performance and benefit from favorable insurance rates and premiums.

Contractor Safety Process

The goal of the Contractor Safety Program is to ensure contracted work conforms to all applicable regulations and Xerox environment, health and safety requirements. Contractors are qualified to the safety and health requirements prior to beginning work at a Xerox location. Contractors are required to submit a job safety plan and workers on U.S. Xerox sites must attend an orientation session. Incidents and injuries are tracked both as feedback and to measure program effectiveness. Although first established in our Webster, New York, operations, this model has been applied successfully in many of our larger locations.

Xerox also functions as a contractor for many Xerox client accounts. We have in place and follow our internal safety standards, and we establish safety plans, deliver specific employee training and maintain management oversight to ensure our operations meet both Xerox and client requirements.

Workplace Health Management

Our workplace health programs include processes for emergency medical response, the characterization of employee fitness for duty, and pre-employment drug testing. In addition, programs are in place for conducting medical exams in connection with safety-sensitive work, and drug testing and immunizations based upon specific work operations and client accounts.

Preventing and Monitoring Workplace Exposures

To protect employees from unsafe exposures to chemicals, noise and radiation, Xerox applies exposure limits to worldwide manufacturing, research and technology service operations based upon the Threshold Limit Values (TLV) recommended by the American Conference of Governmental Industrial Hygienists. These reflect the best advice of a widely respected committee of international experts. However, in jurisdictions where government regulations are more stringent, Xerox meets those regulatory requirements. For some materials — including toners and certain solvents and metals — Xerox has established exposure limits that are more stringent than the TLV or existing regulations and standards.

Using the Xerox Exposure Assessment process industrial hygienist and safety professionals monitor, assess and report workplace exposures. Effective process design, engineering controls, safe job procedures and personal protective equipment are utilized to control exposures and protect employee health. Medical surveillance programs are in place to monitor the health of employees working in operations with specific jobs and hazards (e.g., high noise, organic solvents). Results of those medical exams are reviewed by health care professionals to ensure employee wellness.

Of the workplace exposures monitored in 2016, all were within regulatory limits. When necessary inhalation exposures were controlled through the proper use of personal protective equipment where additional engineering controls were not feasible.

Environment, Health and Safety Project Reviews

We continually make modifications to facilities, work processes and operations to improve efficiency and effectiveness. To ensure these changes meet applicable Xerox safety standards consensus standards and regulatory requirements, projects are reviewed by occupational safety and health professionals. The scope of the project is defined, potential safety and environmental impacts are characterized, and control requirements are established and communicated before the project is initiated. The process serves to inform the engineering and management teams on safety requirements and ensures all project designs have controls integrated into work plans. The process ensures environmental, health and safety requirements are understood and implemented at the beginning of the project.