UK printer delivers high-value projects while lowering environmental impact

Rapidity gains efficiency, versatility with Xerox® Iridesse® Presses

“When you put the capabilities of the Iridesse® Press together with Xerox’s service model, I don't think anything else competes quite honestly.”

About the client

Awarded 2024 Bespoke Digital Printer of the Year by Printweek, Rapidity is a family-owned, commercial printer located in Central London. It provides high-value custom services to a wide array of customers.

Case Study Overview

Established in 1986, Rapidity is one of London’s top printing services, using cutting-edge technology to deliver high-quality printing and finishing. In the face of an industry-wide reduction in print volume demand in recent years accelerated by the pandemic, the award-winning company decided to refocus its business on providing higher-value, lower volume customised print services. It also decided to center its operation in Central London to improve energy efficiency and take advantage of a robust rebound in business there.

As part of a multi-year refurbishment of its Central London building, Rapidity set out to replace its large, liquid toner presses with smaller, more versatile dry-ink presses that would deliver high-quality inline embellishments with increased energy efficiency.

After reviewing market offerings, it turned to Xerox for a solution. A former longtime customer of Xerox, Rapidity chose to “come home” to Xerox with the Xerox® Iridesse® Production Press that offers digital CMYK plus speciality ink capabilities. It installed four Iridesse Presses within six months and seamlessly launched the new technology over a single weekend in October 2023.

Rapidity is getting “excellent” printing service results with increased productivity and has reduced its energy use by 60 percent.

The Challenge

Adapt to changing demand with smaller footprint, more versatile presses

Rapidity, a family-run, London-based printer, has been providing high-quality printing and finishing services for a vast range of direct marketing, display and creative print solutions for more than 30 years. In recent years, the company and the print industry have seen a decline in demand for high-volume printing as the internet displaced commoditised work.

In 2020, Rapidity was on track to refurbish its building in Central London and centralise its operations there to further its efforts to reduce its carbon footprint. When the project was delayed due to the pandemic, Rapidity Managing Director Paul Manning says his company regrouped and decided to rethink its business strategy. While high-volume jobs like flyers, stationery and business cards were shrinking, the company found a growing demand for high-value custom jobs like invitations, brochures and packaging with more embellishments, speciality colours, unique substrates and premium finishing.

Rapidity decided to refocus on low-volume, bespoke speciality work that would tap into the robust rebound in business in Central London. As part of the shift, Manning noted, it made sense to replace its large, liquid toner presses with smaller, more versatile dry-ink presses that would deliver high-quality inline embellishments with increased energy efficiency. The contracts on its older presses were expiring and it wanted to invest in new equipment to coincide with a move to its refurbished building.

The new presses needed to be easy to use, offer a wide range of high-quality print capabilities, and be energy efficient. They also needed a smaller physical footprint to meet space challenges in the new site.

“We didn't want to end up with some complicated, heavy machinery that would suck the life out of the local energy grid. That's how we came back to the Xerox® Iridesse® Press, really.”

The Solution

Energy-efficient digital presses that go Beyond CMYK

Rapidity decided to return to dry ink-based digital equipment to replace its liquid ink presses. Not only has speciality ink technology improved over the past decade, Manning notes, but customer preferences have shifted from the traditional lithography standards to striving for images that looked like what is on a digital screen.

After reviewing marketing offerings, Rapidity reached out to Xerox for a solution. A longtime Xerox customer in the past, Rapidity was familiar with Xerox products and valued its reputation and its service model.

They found the Xerox® Iridesse® Press offers the high-quality images, speciality ink capabilities, and ease of use it wanted. Iridesse is ENERGY STAR® certified, demonstrating it meets stringent energy efficiency criteria. It has a “tiny” physical footprint and is backed by 24/7 product support. Rapidity also took advantage of Xerox Genesis Initiative training resources to better design for digital embellishments.

The Xerox® Iridesse® Press is backed by an intelligent ecosystem of automated and AI assisted solutions, including XMPie® technology to create personalised communications for customers and powerful Xerox® FreeFlow® Core workflow management software. “So that's why we got four of them,” Manning says. “Because they do everything for us, from direct mail to normal work, to embellishments, to prototype packaging, to you name it. It just ticks every box that we needed to tick.”

“There's a press that's similar to the Iridesse from another manufacturer, but really we wanted to come home to Xerox essentially.”

The Results

Amazing print service results, reduced energy use

Rapidity installed four Xerox® Iridesse® Presses over six months and launched the new technology in a single weekend. Because many of its staff members had used Xerox presses previously, the transition was very quick.

Manning says the new presses are producing “amazing” results for customers, who can leverage a range of speciality features in a more collaborative creative process, especially metallic, fluorescent, white and clear inks on speciality stocks.

Company productivity “is through the roof,” he says, due to the ease-of-use as well as the 24/7 maintenance services. Its main production engineer is now freed up from the time-consuming task of maintaining the aging presses and is extremely happy with being able to just run print jobs without interruption.

Rapidity has had a 60 percent decrease in power usage over three months. While the refurbished building has many energy-efficient features, Manning says the new presses are the largest factor in the power use reduction.

He says that Rapidity has only just begun to tap into the high-value custom market, which he says has considerable potential for growth.

The Challenge

Rapidity decided to refocus its business on high-value, lower-volume custom print services.

The contracts on its older, ink-based presses were expiring and it wanted to invest in new, more efficient equipment to coincide with a move to its refurbished building in Central London.

They needed more versatile digital presses that would deliver high image quality as well as speciality inks, metallics and embellishments required by a shifting mix of print work.

The presses needed to be energy efficient in keeping with its efforts to reduce its environmental impact.

They wanted easy-to-use equipment that wouldn’t require a significant ramp-up process.

They also sought a reliable service model to eliminate the ongoing engineering maintenance demands its older presses required.

The Solution

After reviewing market offerings, Rapidity decided to return to working with Xerox which had a proven track record and would provide an easy transition to products it knew.

Rapidity installed four Xerox® Iridesse® Production Presses to provide the speciality ink capabilities to embellish bespoke print work.

The Iridesse presses fit in a small physical footprint, meeting space requirements in the refurbished company building.

XMPie® technology lets Rapidity create personalised communications for customers seamlessly, at scale.

Xerox® FreeFlow® Core pre-press software provides intelligent automation for workflow management.

The equipment is backed by Xerox 24/7 support model.

The Results

Ease of use and previous experience with Xerox presses meant the company was able to switch on the new presses over a single weekend, getting Rapidity up and running quickly.

Productivity is “through the roof,” with easy-to-use presses.

Presses provide high-quality results on a wide range of services, from direct mail to normal work, to embellishments to prototype packaging.

Rapidity has seen a 60 percent decrease in energy use, which the presses contributed to substantially.

Meet the Xerox® Iridesse® Production Press

Xerox® Speciality Dry Inks

Add a new dimension to the page, and to your print business.

Related Articles

Solving Print's Pain Points

Explore the latest trends and solutions in print operations with Printweek’s special supplement, sponsored by Xerox. Gain insights into digital transformation, efficiency, and sustainability for your print business.

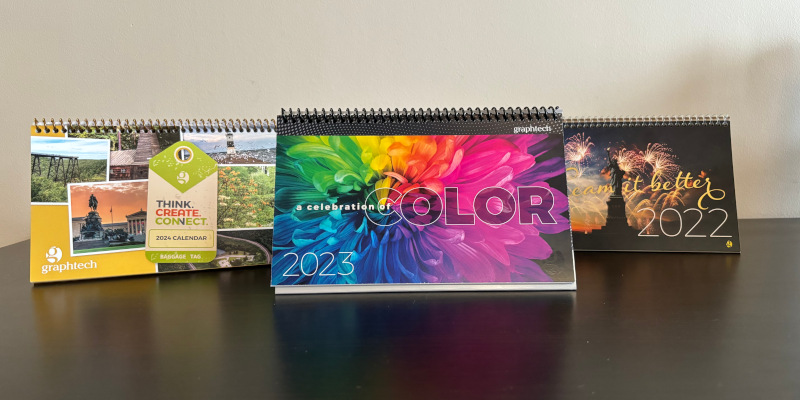

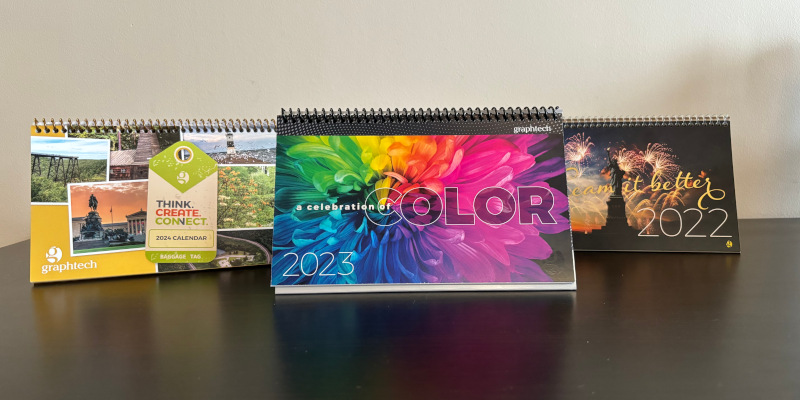

Spectrum Print Plus – The Business of Colour, Clients, and Commitment - Xerox

“After months of rigorous evaluation, the clear winner had been right in front of us all along—it was the Iridesse!”

Xerox Iridesse Virtual Designer Training

Add popular digital Beyond CMYK embellishments to your projects when using the Xerox Iridesse Press.

Xerox® Iridesse® Presses: Empowering Clients with On-Demand Printing

See how Xerox® Iridesse® Presses helped a client meet complex client needs with on-demand printing, exact quantities, and specialty embellishments, all while maintaining high standards.

Virtual Designer Training: Xerox Adaptive CMYK+ Kit

Use popular digital embellishment techniques in your designs with adaptive CMYK+ kits on the Xerox Versant and Xerox PrimeLink Production Press

Unlocking Profits with Digital Embellishments

Get ready to dazzle your clients and boost your bottom line with this power training session from Xerox and Taktiful. Learn strategies to become more profitable marketing, pricing and selling Beyond CMYK applications.