Inside the Baltoro™: Xerox Inkjet Heads Make All the Difference

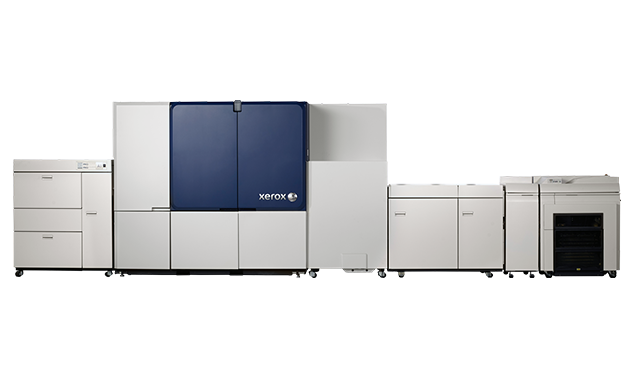

In 2019, Xerox debuted another industry first: the Baltoro HF Inkjet Press. Half the size of other presses, the Baltoro offers true HD 1200x1200 dpi print resolution and prints on a range of media with no primers and precoats. At the center of this first-of-its-kind press is the Baltoro’s High Fusion (HF) W-Series Inkjet Heads.

How our HF inkjet technology stacks up against offset and toner

Here our head of printhead research and development, Chad Slenes, discusses how Xerox’s heads differentiate the Baltoro.

How do the HF W-Series Inkjet Heads bring new capabilities to the inkjet market?

First, our printheads contribute to what is now the broadest media flexibility in the entry-level, cut-sheet, production inkjet market. The printhead’s small drop sizes also help enable direct printing onto a range of media with high-definition image quality and color without any primers or pre-coats. This means no fifth liquid is required, reducing the size of the press, its power consumption and total cost of ownership. Finally, we believe this printhead offers unmatched reliability.

How do these heads offer unmatched reliability?

We have more than 25 years of reliability metrics and testing under our belts. Our robust testing process includes running four sets of long-term tests and quick-level tests that are done in a manufacturing setting. These tests check for various elements such as longevity, thermal cycles and conditions and fluidity. With our W-Series testing, we’ve successfully passed 500 billion cycles on 10 printheads and have run more than 100,000 liters through a single printhead. These tests are done over a five-year period, so we know how the printhead will behave and help ensure it meets Xerox’s strict quality standards throughout its lifecycle.

You discussed having 25 years of reliability metrics. How long has Xerox been engineering inkjet heads?

Some are surprised to learn that Xerox has been developing inkjet printheads since 1986.

Tell us about the engineering team behind these innovative printheads.

Many of our engineers have been with us since 1986, demonstrating our deep subject expertise in this area. Today we have more than 250 subject matter experts engineering and manufacturing our printheads at our center in Wilsonville, Oregon. Over the years, this team has helped build and ship more than 2.5 million printheads!

What’s on the horizon for Xerox inkjet heads?

We believe there’s an opportunity to bring our W-Series to other production inkjet products in the future. We are now testing our heads in environments beyond graphic arts such as textiles, label making and 3D. Today many 3D printers in the industry use our printheads. This includes our own 3D liquid metal printer, which is still in development. Thanks to our printheads and IP in this space, Xerox is able to create denser, faster and more consistent metal parts, positioning us to leapfrog the competition in the 3D market.

Xerox® High Fusion Ink

Take the cost out of print manufacturing. Extend inkjet benefits to offset coated stocks.

Xerox® Baltoro® HF Inkjet Press

Transformative performance and economics delivered through inspired innovation

Xerox® High Fusion W-Series Printhead

The future of inkjet.Powered by Xerox.

Related Articles

How Print Service Providers Can Drive Profitability

Download our checklist to help you stay ahead of industry headwinds and be more profitable while managing the shift toward shorter, faster turnaround jobs.

Improved Student Engagement

See how using Xerox® Baltoro® HF Inkjet Press helps school DCMO BOCES deliver more-engaging educational content while saving significant costs.

Power Up Your Production Print Profitability

Our infographic provides an at-a-glance look at the latest industry intelligence to help put your production print operation on the path to profit and growth. Download it now.

UK printer delivers high-value projects while lowering environmental impact

Rapidity gains efficiency, versatility with Xerox® Iridesse® Presses

Getting Started with Xerox® FreeFlow® Core

Join our Xerox virtual webinar to help streamline your pre-press workflow and say goodbye to touchpoints and bottlenecks.

Solving Print's Pain Points

Explore the latest trends and solutions in print operations with Printweek’s special supplement, sponsored by Xerox. Gain insights into digital transformation, efficiency, and sustainability for your print business.